Organic compounds, abbreviated as organic compounds, refer to compounds that contain certain carbon elements, but do not include carbon oxides, sulfides, carbonic acid, etc< Br>

Common classifications of organic compounds include hydrocarbons, aromatic hydrocarbons, alcohols, phenols, ethers, aldehydes, ketones, carboxylic acids, esters, etc. The following are common organic compounds< Br>

Gaseous: methane (CH4), acetylene (C2H2), propane (C3H8), formaldehyde (CH2O)

Liquid state: benzene (C6H6), toluene (C7H8), ethanol (C2H6O) cyclohexanone (C6H10O), ethyl acetate (C4H8O2), acetone (C3H6O)

Solid state: glucose (C6H12O6), amino acids (RCH (NH2) COOH), proteins, plastics, rubber, fibers, etc< Br>

Biopurification technology utilizes microorganisms to biodegrade waste gas, causing pollutants to decompose and transform into harmless or less harmful substances. Microorganisms use organic matter as the substrate for their growth and reproduction, and through different transformation pathways, large molecules or structurally complex organic matter are ultimately oxidized and decomposed into simple inorganic substances such as water and carbon dioxide. At the same time, through assimilation and utilization of the energy generated during the alienation process, microbial organisms grow and reproduce, creating favorable conditions for further enhancing their ability to treat organic matter.

Purification devices are generally suitable for treating waste gases with hydrogen sulfide content less than 500 mg/m3, total alcohol and ester content less than 400mg/m3, total organic amine/ammonia, benzene, toluene, xylene, ethylbenzene, thiol/ether content less than 200mg/m3, and total chloromethane and chlorobenzene content less than 100mg/m3. Under the applicable conditions of the purification device, the purification efficiency of hydrogen sulfide should be greater than 85%, the purification efficiency of alcohols and esters should be greater than 80%, and the purification efficiency of benzene, toluene, and xylene should be greater than 50%

Biological treatment processes are mainly divided into biological filtration, biological drip filtration, and biological washing.

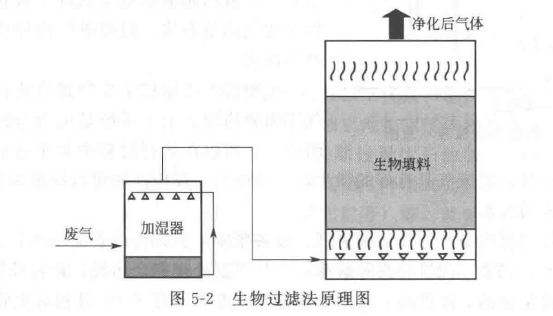

1. Biofiltration method Biofiltration process is a traditional form of biological method suitable for treating difficult to biodegrade waste gas. It mainly consists of a humidifier and a biological bed, which uses materials such as soil, peat, bark, compost, etc. as fillers for biological strains, utilizing the nutrients of the fillers themselves without the need for additional nutrients. After the exhaust gas is connected to the humidifier, it is humidified and then comes into contact with the biofilm attached to the filler. It is adsorbed and degraded by microorganisms, and ultimately converted into carbon dioxide and water. The treated gas is then discharged from the other end of the biofilter (Figure 5-2). The characteristics of biological filtration method are easy to start and operate, simple operation, low operating cost, but difficult to control reaction conditions, and large equipment volume.

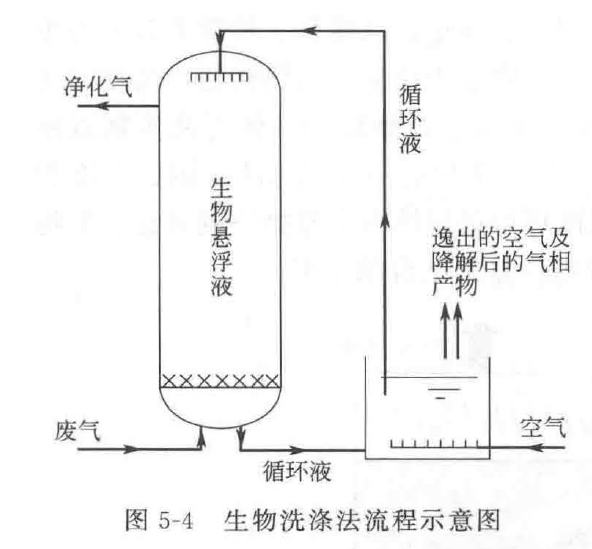

2. Biological washing method Biological washing method, also known as biological absorption method, is suitable for treating soluble organic waste gas. The biological washing system generally consists of a washing tank and a bioreactor (regeneration tank) with activated sludge, as shown in Figures 5-4. The biological washing method has low pressure loss, small equipment volume, and can simultaneously contain organic waste gas with dust content. The disadvantage is that the treatment efficiency of insoluble components in exhaust gas is very low.

3. Biological drip filtration method

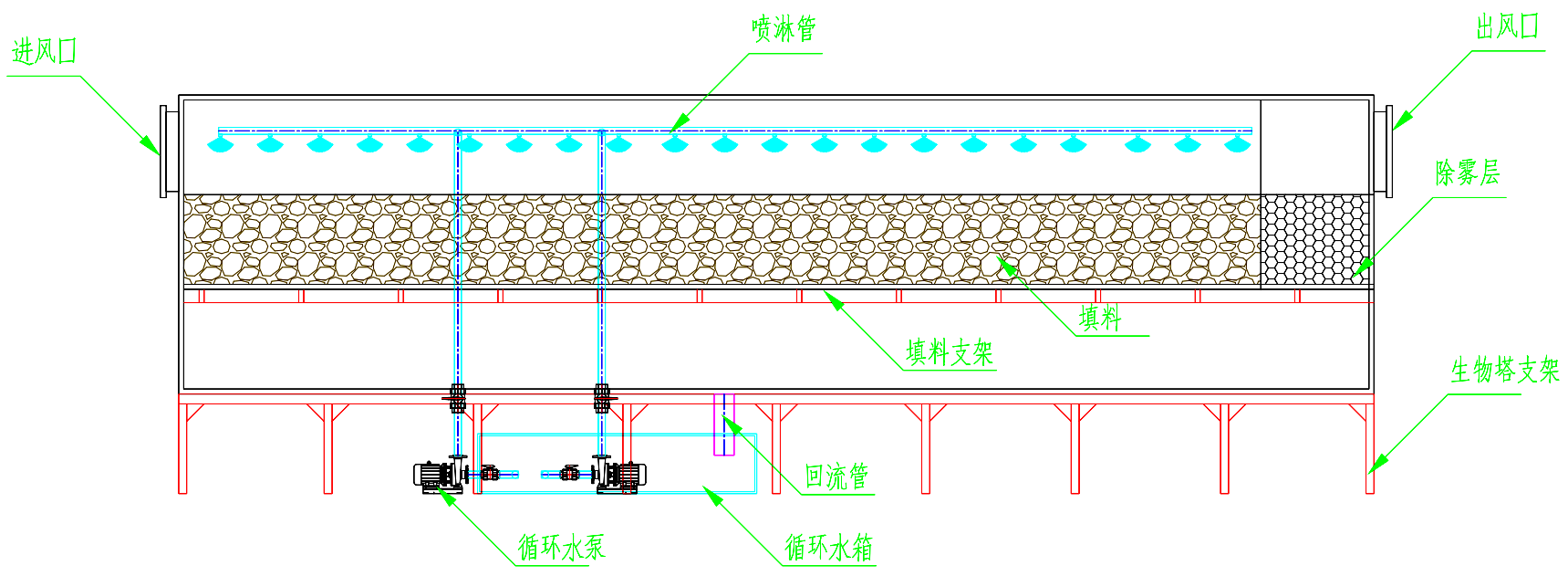

Biological drip filtration is a biological treatment technology that falls between biological filtration and biological washing, and is the most commonly used form of biological treatment. He mainly consists of a biological bed, a humidification system, and a dosing system<

In biological drip filtration reactors, inert fillers such as ceramics, volcanic rocks, perlite, crushed stones, plastic materials, etc. are generally filled. In this system, the fillers only provide a certain attachment surface for microorganisms. The exhaust gas comes into contact with biofilms (microorganisms) growing on inert fillers, resulting in biodegradation<

The circulating liquid sprays downwards from the top of the reactor and drips down along the packing, providing microorganisms with the necessary water and nutrients for organic matter degradation. Therefore, the operating reaction conditions (such as pH, temperature, and nutrition) of the biological drip filtration method are easy to control, and the nutrients required by microorganisms can be added to the circulating liquid.

1. Nutrient solution: The proportion of carbon, nitrogen, phosphorus, potassium, and sulfur components should be reasonably prepared based on the actual composition of the exhaust gas. Generally, it is recommended to be 100:10:4:1:1, and in special circumstances, trace elements involved in biological metabolism should be added<

2. Temperature: The suitable temperature range for the microbial bed of the purification device is 15-40 ℃. In the north, insulation layer should be installed below the biological tower, and in winter, the heater should be turned on in the circulating water tank to maintain the temperature of the circulating water<

3. Microbial activity:Observe the activity and quantity of biological bacteria through microscopic examination, and also conduct regular testing of exhaust gas to determine changes in the activity of biological bacteria based on the efficiency of exhaust gas treatment. To ensure the stability of bacterial strains, it is recommended to add 5kg of biological strains per ton of circulating liquid per month<

4. Humidity: The relative humidity of the inlet exhaust gas of the biological tower should be greater than 90%<

5. PH value:The pH value is 6.0-9.0. If the exhaust gas contains acidic or alkaline components, an alkaline or acid washing tower should be installed in the front section of the biological drip filter tower<

6. Oxygen content: Biological bacteria require oxygen to participate in the decomposition process, and under normal working conditions, there is no need to control oxygen. For example, during holidays, the fan can be regularly turned on to fill with oxygen to ensure the activity of the organism.