Pharmaceutical wastewater has different water quality due to different products, raw materials, and process methods. However, overall, pharmaceutical wastewater has a high content of organic pollutants, toxic substances, difficult to biodegrade substances, and high salt content, making it a highly hazardous industrial wastewater. The combination of advanced oxidation technology pretreatment and advanced anaerobic treatment technology can meet environmental protection requirements.

The source of food wastewater comes from the cleaning of food raw materials and the wastewater generated during food processing. The main pollutants in food wastewater are organic pollutants and fats, with high concentration and good biodegradability. Oil separation and biochemical treatment processes are usually used.

The wastewater produced during the metal electroplating process contains metal ions and other organic compounds, which contain a large amount of metal ions, have low or high pH values, contain organic compounds, and have an odor; Electroplating wastewater has the characteristics of high concentration, difficult degradation, and serious environmental pollution, making it difficult to treat. Chemical precipitation, neutralization, ion exchange, RO reverse osmosis and other technologies are often used for treatment.

The wastewater generated from processes such as grinding, etching, electroplating, hole metallization, development, and film removal in the production of circuit boards mainly includes chelating wastewater, heavy metal wastewater, and high concentration organic wastewater. Classify and collect PCB wastewater according to its characteristics, and use processes such as network breaking, precipitation, acidification slag removal, acid-base neutralization precipitation, and biochemical treatment to treat wastewater from different production processes.

The wastewater from chip semiconductor production generally includes copper containing wastewater, organic wastewater, fluorine containing wastewater, acid-base wastewater, and heavy metal wastewater, and the biodegradability of the wastewater is poor; This type of wastewater needs to be classified and collected before being treated through advanced oxidation and biochemical technologies.

The wastewater from the new energy industry generally contains heavy metals (nickel cobalt manganese lithium) as well as high concentrations of organic matter, ammonia nitrogen, and total nitrogen; For the treatment of such new energy battery wastewater, traditional sedimentation methods are no longer able to meet the increasing environmental requirements, and advanced catalytic oxidation, electrocoagulation, MVR evaporation and other physicochemical treatment technologies are needed. Biochemical treatment requires the use of multi-stage anoxic and aerobic treatment technologies.

Petrochemical wastewater is the wastewater discharged by petrochemical joint enterprises, mainly including oily wastewater, phenolic wastewater, sulfur-containing wastewater, cyanide wastewater, aldehyde wastewater, and acid-base wastewater. The wastewater has a large amount of water, complex and fluctuating water quality, high organic matter concentration, and heavy metal content, requiring the use of air flotation, flocculation, and catalytic oxidation treatment processes. At the same time, the biodegradability of the wastewater is poor and the concentration is high, requiring the use of advanced anaerobic treatment technology for treatment.

The main pollutants in printing and dyeing wastewater include impurities such as cotton, hemp, silk, and wool, as well as surfactants, dyes, auxiliaries, pH, high concentration, and high chromaticity. Based on the characteristics of printing and dyeing wastewater, sedimentation, flocculation, filtration, and advanced catalytic oxidation technologies are often used to remove turbidity, suspended solids, and chromaticity. Anaerobic and aerobic treatment processes are used to remove organic pollutants from the wastewater.

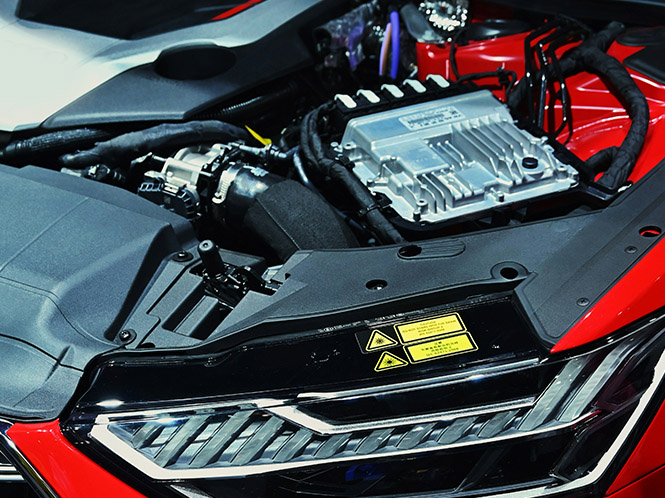

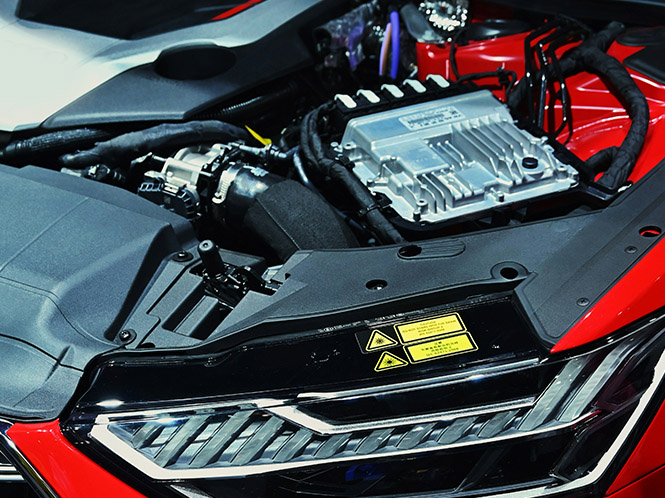

Wastewater containing pollutants such as organic matter, metal ions, and fats generated during the production process of automotive parts is treated using different treatment processes such as physicochemical pretreatment, biochemical treatment, and RO reverse osmosis for different types of automotive parts wastewater.

In general, papermaking wastewater contains a large amount of suspended solids, organic matter, ammonia nitrogen, phosphorus and other substances, which need to be treated through primary treatment processes such as hydraulic screening, grids, sedimentation tanks, biochemical treatment processes, filtration, disinfection and other advanced treatment technologies.

Nitrobenzene, nitrophenol, nitrotoluene, phenol, aniline wastewater, and benzyl ether wastewater; Wastewater containing dispersed dyes, cationic dyes, and weakly acidic dyes; Synthetic pharmaceutical and pesticide wastewater; Veterinary medicine wastewater; Fine chemical wastewater; Synthetic resin wastewater; Cyanide containing wastewater; Fluorine containing wastewater; Wastewater containing anthracene; Coking wastewater and electroplating wastewater are both types of chemical wastewater.

Industrial plating cleaning water, waste plating solution, equipment cooling water (cooling water is not contaminated during use except for temperature rise), other wastewater (flushing workshop floor, scrubbing electrode plate washing water, ventilation equipment condensate water, and various tank liquids and drainage caused by plating tank leakage or improper operation management), wastewater mainly contains heavy metal ions such as chromium, cadmium, nickel, copper, zinc, gold, silver, and cyanide, some of which are highly toxic substances that cause cancer, deformity, and mutation.

process flow

The wastewater generated from processes such as grinding, etching, electroplating, hole metallization, development, and film removal in the production of circuit boards mainly includes chelating wastewater, heavy metal wastewater, and high concentration organic wastewater. Classify and collect PCB wastewater according to its characteristics, and use processes such as network breaking, precipitation, acidification slag removal, acid-base neutralization precipitation, and biochemical treatment to treat wastewater from different production processes.

Food wastewater mainly comes from the raw material cleaning section, production section, and forming section. According to the classification of the raw materials used, the wastewater can be divided into meat and meat product industry, poultry and egg processing industry, dairy processing industry, sugar industry, poultry and egg processing industry, starch industry, fermentation industry, seasoning, oil industry, food additive industry, etc. The main components of food wastewater include a large amount of sand and debris, leaves, skin, scales, meat, feathers, hair, etc., which enter the wastewater, causing it to contain a large amount of suspended solids.

Pharmaceutical industry wastewater refers to the wastewater discharged from factories that manufacture antibiotics, antibiotics, antiserum, and organic and inorganic pharmaceuticals. The amount and quality of wastewater vary depending on the type of drug produced. Antibiotics, antiserum, and other production wastewater, except for animal organ based wastewater and herbal based plant-based wastewater, are not included. The main components of sewage: Pharmaceutical industry sewage generally contains toxic substances such as fluorine, cyanide, phenol, cresol, and mercury compounds, as well as colloidal substances.

The wastewater from semiconductor industry production is mainly divided into three categories: fluorine containing wastewater, copper containing wastewater, and ammonia containing wastewater. The dissolved solids and suspended solids in semiconductor wastewater differ in content, pH, and metal impurities. The main pollutants in sewage are Ag, Cu, Ni, COD, SS, CN, acid alkali, HF concentrated waste liquid, HF washing wastewater, acid and alkali wafer grinding wastewater, etc.

Domestic sewage includes urban and rural domestic sewage, which is mainly the wastewater discharged from residents' daily lives. The wastewater contains organic substances such as proteins, carbohydrates, fats, urea, ammonia nitrogen, as well as pathogenic microorganisms such as parasitic eggs and intestinal infectious viruses. Wastewater generated from residential, government, school, hospital, shop, public places, and industrial enterprise toilets is a type of domestic sewage.

Acid mist exhaust gas poses great harm to the environment and human health. Firstly, acid mist exhaust gas can cause serious pollution to the atmospheric environment, leading to the formation of acid rain. Secondly, acid mist exhaust gas can harm plant growth and disrupt ecological balance. Acid mist exhaust gas can also pose a threat to human health, causing diseases in the respiratory system, skin, and other areas. The treatment methods for acid mist exhaust gas are currently mainly divided into physical methods and chemical methods.

Plastic products produce a large amount of volatile organic pollutants during the production process. These harmful gases not only pollute the air and damage the environment; And it also poses a threat to human health. At present, there are several methods for the treatment of plastic processing waste gas, including adsorption, combustion, biofiltration, photochemical conversion, plant liquid-phase spray washing, and plasma air purification

The paint mist and volatile organic solvents generated during painting, if discharged directly into the air without treatment, can cause great harm to human health and the atmospheric environment. There are mainly three effective treatment methods: 1. filtration combined with activated carbon adsorption; 2. Filter combined with catalytic combustion method; 3. Water spray and activated carbon adsorption.

The waste gas from screen printing is mainly organic waste gas generated during the evaporation of ink during manual or mechanical screen printing processes. The main components of the waste gas are benzene, toluene, and xylene waste gas. The volatilization or emission of these organic waste gases into the air can pollute the environment, affect the growth of animals and plants, and pose a threat to the health of surrounding residents. Therefore, it is necessary to purify and treat the waste gas from the screen printing factory to meet the emission standards.

The harm of polishing and polishing dust and smoke to the human body is related to the size of particles: particles larger than 5 microns can be blocked by nasal hair and respiratory mucus, while particles smaller than 0.5 microns generally adhere to the surface of the upper respiratory tract and are discharged with sputum.

Polishing is the process of removing a metal surface with a hard substance. Generally, grinding wheels and grinding stones are made by pressing hard abrasive materials together. Commonly used materials such as aluminum oxide and silicon carbide can be adhered and pressed onto fiberboard, paper, or cloth for manual polishing. Just like diamond powder particles can also be used as abrasives.

Woodworking dust mainly comes from the cutting, processing, polishing and other processes in wood processing. Due to the high concentration of dust generated by woodworking equipment during the processing, the commonly used high-efficiency pulse bag dust removal technology in China is adopted to recover dust and purify exhaust gas, ensuring that all emission indicators meet the emission requirements.

Printing waste gas treatment is an important environmental issue, as the printing process produces various harmful substances such as dust, organic waste gas, and smoke.

Welding smoke is a type of smoke generated during the welding process, when the welding rod comes into contact with the workpiece, under high temperature combustion conditions. This type of smoke contains manganese dioxide and nitrogen oxygen

Chemicals, fluorides, ozone, etc., float in the air and cause harm to human health. After inhaling this kind of smoke and dust, people can cause dizziness, headache, cough, chest tightness, and shortness of breath,

Severe cases can lead to smoke poisoning or pneumoconiosis.

Generator exhaust gas treatment refers to the treatment and purification of the exhaust gas emitted by the generator to reduce its pollution to the environment and harm to human health. With the continuous development of industrialization and urbanization, the use of generators is becoming increasingly widespread, and their exhaust emissions have become a serious environmental problem.

In order to control kitchen oil fume pollution, a new type of air curtain range hood is designed based on the analysis of the mechanism and characteristics of kitchen oil fume generation, and a smoke control flow field formed by air curtain technology can prevent kitchen oil fume from overflowing. A closed flow field theory was proposed for the wind curtain range hood, and a mathematical model of the closed flow field was established based on the principles of aerodynamics, fluid dynamics, and potential flow superposition.

Organic waste gas refers to gas waste containing organic substances. This type of exhaust gas usually comes from industries such as chemical, printing and dyeing, pharmaceuticals, and painting. The main components of organic waste gas are volatile organic substances, such as benzene, toluene, xylene, etc. These substances have toxic effects on the human body and long-term exposure can cause diseases such as cancer.

Inorganic waste gas refers to gas waste composed of inorganic substances, such as ammonia, chlorine, sulfur dioxide, etc. This type of exhaust gas usually comes from industries such as refining, steel, and electricity. The harm of inorganic waste gases to the environment is mainly manifested in acid rain and air pollution.

Dust exhaust gas refers to gas waste containing solid particulate matter. This type of exhaust gas usually comes from industries such as coal, cement, ceramics, etc. Dust and exhaust gases can cause serious pollution to air quality and pose a threat to the human respiratory system.

Stinky waste gas refers to gas waste containing foul smelling substances. This type of exhaust gas usually comes from industries such as garbage treatment and animal husbandry. Stinky exhaust gas can pose a threat to the surrounding environment and human health.

Air compressors are commonly used equipment in industrial production, and one of the problems with this type of equipment is the high noise level, especially in the air compressor room. When many air compressors are working, the noise level of the entire machine room will far exceed the hygiene standards of the industrial area, and even affect the factory environment. Let's take a look at how to reduce the noise of air compressors.

With the development of society, generators play an important role in many fields, such as airports, communication, oil, electricity, military field use, factory production, and people's ordinary lives. Especially in heavy industries such as oil factories and power plants. But as the application of generators becomes more and more widespread, it brings convenience and speed to our daily work. At the same time, the noise generated by generators also poses a certain degree of harm to the surrounding environment.

Cooling towers can generate noise during operation, causing serious impacts on the lives of surrounding residents. The following methods can be used to reduce the noise of the cooling tower: noise reduction treatment, installation of sound barriers, shock absorption and sound insulation measures, and replacement of low-noise equipment components.

Highway noise can be treated in the following ways: installing sound barriers, applying low-noise road surfaces, planting green belts, strengthening road traffic management, and installing soundproof windows

Implement measures and responsibilities for the declaration and registration of hazardous waste, and assign a dedicated person to handle the declaration and registration of hazardous waste in the unit through the Provincial Solid Waste Management Information System. It is necessary to truthfully declare the generation, utilization, and disposal of hazardous waste from the previous year through the Provincial Solid Waste Management Information System before the specified date each year.

Environmental supervision refers to the environmental supervision and management carried out by the environmental supervision agency on the construction of the project, commissioned by the project construction unit, in accordance with the environmental impact assessment documents, the approval of the environmental protection administrative department, and the environmental supervision contract.